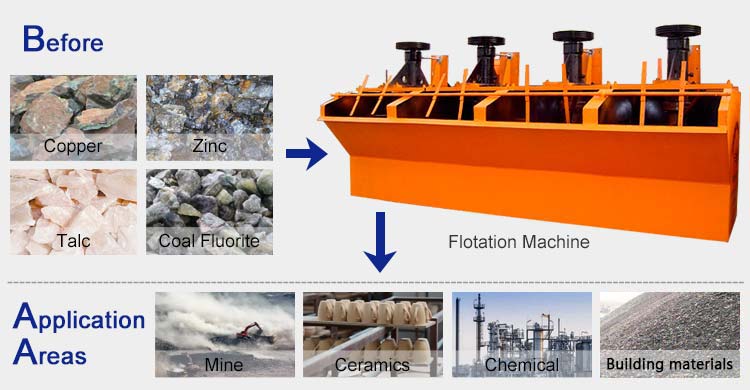

Flotation Machine

Product Model: Various specificiations for choice

Production capacity: 0.2-8 m³/min

Material: coal, fluorite, talc, gold, molybdenum ore, nickel ore, fluorite ore, copper ore, antimony ore, zinc, and tungsten ore,etc.

Product Introduction

1. Flotation machine also called flotation cell, is short of concentrator, which refers to the machinery and equipment used to complete flotation process. To add pulp treated by agentia into flotation cell and stir the air to make some mineral particles selectively flotating above bubbles, and collect the bubbles floating to pulp surface to get foam product, while the rest still remain in the pulp to achieve the purpose of separating minerals.

2. The flotation machine has many forms of structure, and the most commonly used is the mechanical flotation concentrator. Flotation cell is mainly used for sorting copper, zinc, lead, nickel, gold and other non-ferrous metals, and the rough concentration and garbling concentration of black metal and non-metallic.

The performance and characteristics

1. Good wear resistance

2. Good corrosion resistance

3. Strong bonding

4. Excellent impact resistance

5. A wide range of application

The working principle of flotation machine

1. The flotation machine is the first mechanical open type machine to incorporate a vertical circulation of pulp, made possible by combining a “recirculation well” with the distinctive top feed impeller. This arrangement provides positive vertical circulation of pulp similar to the action in a propeller agitator.

.jpg)

2. Pulp from an intermediate zone of the cell is circulated down into the eye of the impeller, mixed with air, and diffused out over the entire bottom of the cell, creating a uniform upward current.

3. This principle varies from most other mechanical open type cells which circulate pulp by lifting it up from the bottom of the cell into the centre of a rotating element.

Technical Data

| Model | Effective Volume (m³) |

Processing capacity |

| XJK-0.35 | 0.35 | 0.18-0.4 |

| XJK-0.62 | 0.62 | 0.3-0.9 |

| XJK-1.1 | 1.1 | 0.6-1.6 |

| XJK-2.8 | 2.8 | 1.5-3.5 |

| XJK-5.8 | 5.8 | 5-7 |

| SF-0.37 | 0.37 | 0.2-0.4 |

| SF-0.7 | 0.7 | 0.3-0.9 |

| SF-1.2 | 1.2 | 0.6-1.6 |

| SF-2.8 | 2.8 | 1.5-3.5 |

| SF-4 | 4 | 2-4 |

| SF-8 | 8 | 4-8 |

| SF-10 | 10 | 5-10 |

| SF-20 | 20 | 5-20 |

| JJF-2 | 2 | 1-3 |

| JJF-4 | 4 | 2-4 |

| JJF-8 | 8 | 4-8 |

| JJF-10 | 10 | 5-10 |

| JJF-16 | 16 | 5-16 |

| JJF-20 | 20 | 5-20 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Get Quotation

Get Quotation

Inquiry Online

Inquiry Online

Get Quote

Get Quote