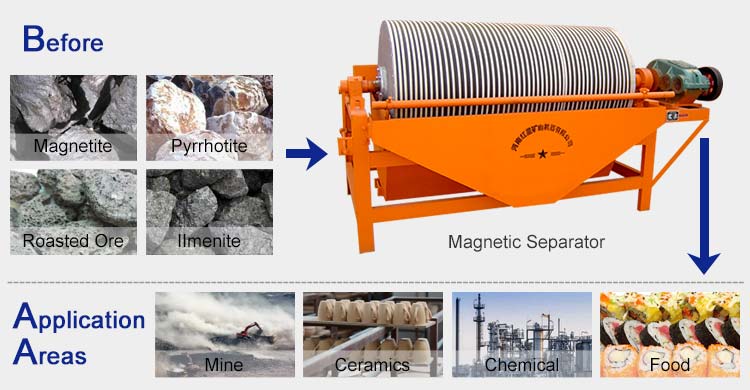

Magnetic Separator

Product Model: Various specificiations for choice

Production capacity: 10-280t/h

Material: magnetite, pyrrhotite, roasted ore, ilmenite, hematite, magnetic mineral, limonite, iron slag election, iron ore dry separation, river sand election iron, and titanium,etc.

Product Introduction

1. The magnetic separator is suitable for wet type magnet separating of magnetite, parroting, roasted ore and limonite. It is also suitable for the iron removal work in coal, nonmetal and construction industries.

2. The magnet system is adopted the combination of high quality ferrite magnetic material and rare earth magnetic steel, the average magnet intensity on the shell surface is 100-600mT. Advantages of this magnet separator are: simple structure, high processing capacity, easy-to-operate and easy-to-maintain.

According to the structure of trough, the wet type permanent-magnet cylindrical type separator can be classified as current type, semi-converse type and converse type.

The wet type permanent-magnet cylindrical type separator is commonly used for separation of iron ore; it is suitable for separating materials with high magnetism; in recent years, these separators have been used as concentrating equipment for replacing the magnetic dewatering cell before filtration.

Technical Data

| Model | Feeding size (mm) |

Processing capacity (t/h) |

| CTB6012 | 2-0 | 10-20 |

| CTB6018 | 2-0 | 15-30 |

| CTB7518 | 2-0 | 20-45 |

| CTB9018 | 3-0 | 40-60 |

| CTB9021 | 3-0 | 45-60 |

| CTB9024 | 3-0 | 45-70 |

| CTB1018 | 3-0 | 50-75 |

| CTB1021 | 3-0 | 50-100 |

| CTB1024 | 3-0 | 60-120 |

| CTB1218 | 3-0 | 80-140 |

| CTB1224 | 3-0 | 85-180 |

| CTB1230 | 3-0 | 100-180 |

| CTB1530 | 3-0 | 170-280 |

Get Quotation

Get Quotation

Inquiry Online

Inquiry Online

Get Quote

Get Quote