Jaw Crusher

Product capacity: 5-2200t/h

Feeding Size: 125-1500mm

Output Size: 10-400mm

Material: pebble, calcite, granite, quartz, concrete, dolomite, bluestone, limestone,coal, basalt, rocks, ore, cement clinker,etc.

Product Introduction

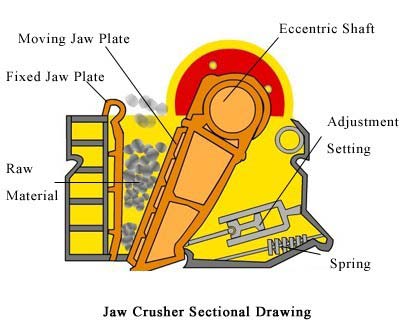

1). Jaw crusher is composed of bracket; jaw; eccentric shaft; jaw plate; spring, etc.

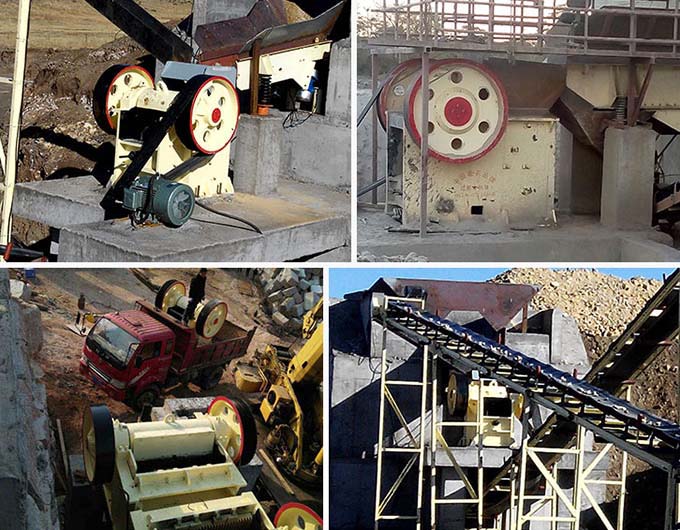

2). One of the most popular stone crushing machines used in mining, metallurgy, construction, road,etc.

3). Widely applied to crush high hardness, mid hardness and soft rocks and ores such as ore,quartz, granite,limestone,slags, construction materials, marble, etc.

4). The maximum compression strength of materials to be crushed is 320MPA.

5). PE series jaw crusher is commonly used for primary crushing, and PEX series is used for secondary crushing and fine crushing.

Performance of jaw crusher

1,World-class manufacturing processes and most advanced production materials

2,High-quality steel castings , driven by two large steel flywheel. Forging stock processes heavy eccentric shaft resulting superior reliability.

3,Bearing housings of jaw crusher for sale is overall steel structure, ensuring its complete fit with the crusher frame and greatly enhancing its radial strength.

4,Finite element analysis techniques,making the crusher a higher strength.

5,Adjustment of the discharge port is more quick and convenient.

6,Larger, more durable eccentric shaft bearings and effective labyrinth sealing make the bearings' life long.

Technical Data

| Model | Max.Feeding size (mm) | Capacity (t/h) |

| PE 150×250 | 125 | 1-3 |

| PE 200×300 | 180 | 2-6 |

| PE 200×350 | 180 | 3-10 |

| PE 250×400 | 210 | 5-21 |

| PE 400×600 | 340 | 16-64 |

| PE 500×750 | 425 | 40-110 |

| PE 600×750 | 500 | 80-240 |

| PE 600×900 | 500 | 50-160 |

| PE 750×1060 | 630 | 110-320 |

| PE 900×1200 | 750 | 220-380 |

| PE 1200×1500 | 1020 | 400-1000 |

| PE 1500×1800 | 1200 | 500-1200 |

| PEX 150×750 | 120 | 8-25 |

| PEX 250×750 | 210 | 13-35 |

| PEX 250×1000 | 210 | 16-52 |

| PEX 250×1200 | 210 | 20-61 |

| PEX 300×1300 | 250 | 16-105 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Feeding opening size(mm) | Max.Feeding size(mm) | Capacity (t/h) |

| HD72(57) | 460×720 | 425 | 50-120 |

| HD86(69) | 580×860 | 500 | 60-280 |

| HD98(751) | 680×980 | 630 | 110-410 |

| HD110(912) | 850×1100 | 750 | 170-550 |

| HD125 | 950×1250 | 900 | 280-750 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Maximum Feeding size(mm) | Capacity(t/h) |

| CJ80 | 410 | 55-335 |

| CJ96 | 480 | 105-390 |

| CJ100 | 600 | 150-420 |

| CJ106 | 560 | 150-500 |

| CJ116 | 608 | 165-580 |

| CJ120 | 700 | 175-610 |

| CJ125 | 760 | 270-831 |

| CJ130 | 800 | 270-831 |

| CJ150 | 960 | 340-880 |

| CJ160 | 960 | 430-1145 |

| CJ180 | 960 | 500-1300 |

| CJ200 | 1200 | 630-1435 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Get Quotation

Get Quotation

Inquiry Online

Inquiry Online

Get Quote

Get Quote